Welcome to Universal Corrosion Prevention India (UCPI)

Project Spectrum

Underground / Buried pipelines / Cross Country Pipelines

Cathodic protection, when applied properly, is an effective means to prevent corrosion of underground plant piping. For many underground applications, such as pipelines, cathodic protection system design is relatively straightforward.

Plant and facility environments, however, are not simple applications. Plants have congested underground piping systems in a tightly spaced footprint.

The presence of copper grounding systems, foundations with reinforcing steel embedded in concrete, conduit, utility piping and structural pilings (either bare or concrete with reinforcing steel) can greatly complicate the task of designing a pipe cathodic protection system.

For simple plant facilities, it is possible to isolate the piping and utilize a conventional galvanic corrosion prevention system. This works only if the plant piping is electrically isolated from other underground structures for the life of the facility.

For most plant and facility applications, it is not practical to isolate the piping from the grounding system for the life of the facility. In these cases an impressed current anode system is the only alternative.

The application of cathodic protection to cross‐country pipelines and in‐plant piping can be completed by thefollowing means:

SACP

- Pre‐packaged anodes

- Ribbon anodes

ICCP

- Horizontal and vertical shallow groundbeds

- Canistered anodes

- Deepwellgroundbeds

Above ground storage tank bases

Tank storage of crude, petroleum, chemicals and other liquids provides a critical interface between production and transportation. Aging infrastructure and the risk of leakage and structural failure is an intolerable risk to terminal operators. This is whyUCPI focuses on providing tank cathodic protection designs, engineering, supply and field services to the tank storage industry in India and aboard.

Cathodic protection is the most common electrochemical technique used to prevent external corrosion on tank floors, and if the product chemistry is correct internal cathodic protection is simple to apply.

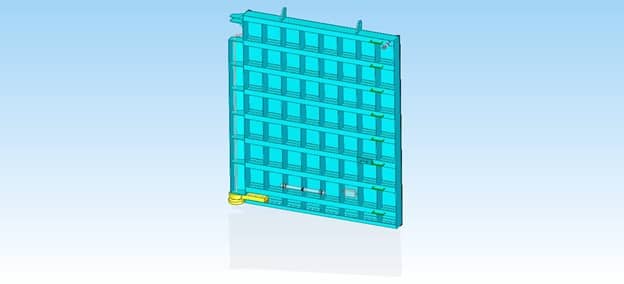

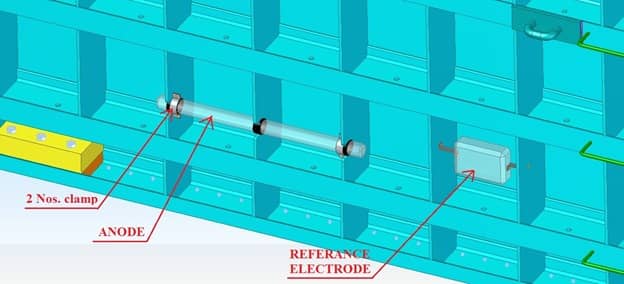

Systems come in a variety of configurations depending on the tank construction, which include; peripheral anodes, mesh anodes, existing floor anodes and carbon disc anodes. For the interior of the tank, rod or bar anodes are commonly used.

Cathodic Protection is accomplished by applying a direct current to the tank surface of the metal, which causes the electrochemical potential of the structure to shift from a corroding state to a polarized and non-corroding state.

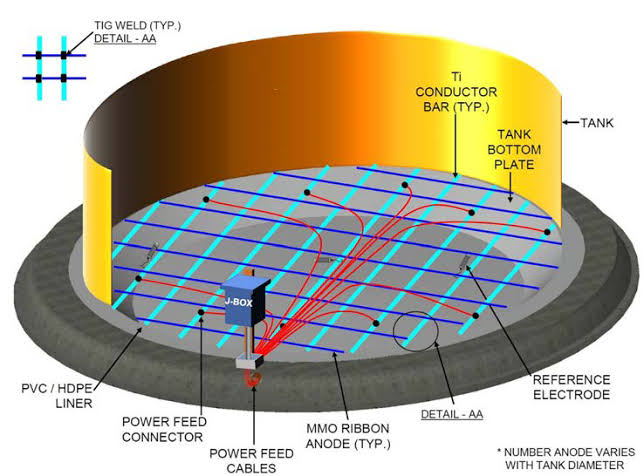

The CP system consists of an MMO coated titanium ribbon anode which runs in parallel straight lines mainly. In one direction. In the other direction runs conductor bar which is titanium ribbon and at each intersection the two are spot welded together. The MMO activated titanium has much lower resistance to earth and current only passes into the soil from the anode.

Power feed connectors and splice kits are used to connect the conductor bar to cables which run through ducts to junction boxes located outside the tank wall.

Cables are then run from the junction boxes to the power supply which is typically located outside the bounded area in a non‐hazardous zone.

To monitor the system permanent reference electrodes can be installed under the tank with the cable tails routed through conduit to outside the tank wall. In addition a perforated plastic tube can be installed under the tank to allow a portable reference electrode to be pulled through to take measurements at regular intervals under the tank.

A similar system can be installed with MMO coated titanium wire running in concentric circles which is also suitable with or without a containment layer.

If a containment layer is not used then it may be necessary to isolate the tank base from other metallic structures with polarization cells. These types of systems can be installed in small gaps and used where new bases are installed on top of an existing base.

Alternatively horizontal, vertical or deepwellgroundbeds can be used to protect tank bases however these can only be used if containment layers are not installed. It is also possible to use SACP in form of zinc or magnesium ribbon in concentric circles or strips to protect tank bases but uses are limited due to the low driving potentials involved.

The CP system consists of an MMO coated titanium ribbon anode which runs in parallel straight lines mainly. In one direction. In the other direction runs conductor bar which is titanium ribbon and at each intersection the two are spot welded together. The MMO activated titanium has much lower resistance to earth and current only passes into the soil from the anode.

External surface of Buried tanks and vessels

The external surface of buried vessels can be protected generally with the same considerations as piping byeither SACP or ICCP and can be bonded into “blanket systems”. If they are not part of a larger system then isolation must be achieved from all other metallic structures including earthing systems typically by polarization cells.

Internal surfaces of tanks, vessels, condensers and pipes

Internal CP of tanks and vessels can be installed on any equipment containing an aqueous phase.Oil storage tanks with aqueous cuts tend to protected by SACP with aluminum anodes welded to the tank base and monitoring system are often not installed.

Water tanks and other aqueous based environments can be protected by either SACP or ICCP with the decision normally based upon the resistivity of the electrolyte.

For SACP anodes are connected directly to the structure. For ICCP anodes can be suspended from the roof, drilled through the tank walls or suspended with non‐metallic eyelets mounted in the tank.

Anodes can be MMO or platinized activated titanium in tubular, wire or ribbon form.

Auto LPG Dispensing Stations (ALDS)

Auto LPG Dispensing Stations (ALDS) can be installed on any equipment containing an aqueous phase. It can be protected generally with the same considerations as piping by either SACP or ICCP.

Submerged and buried steel work of the jacket of an offshore platform

UCPI provides Aluminum anodes to virtually any size or configuration which may be required by an offshore structure or pipeline, which are tailor made to the OFFSHORE STRUCTURES. The submerged and buried steel work of the jacket of an offshore platform is usually left uncoated, and cathodic protection is solely applied to protect these areas. Sacrificial anodes for platforms are generally cast with tubular steel cores which are welded to the jacket bracing members. The current discharged from the anodes will protect the entire steel structure including the buried pipe piles and well castings. In the case where continuous monitoring of the platform potential is required, permanent potential monitoring equipment including the monitoring anodes and monitoring instruments can be installed on the platform. The columns or legs of jack up drilling rigs are generally coated with high performance protective coatings whereas the spud cans or mat are often left uncoated.

When designing a cathodic protection system for a jack-up rig, the constraints by the rig operations must be taken into consideration. This would require the positioning of the anodes on the legs or spud can so as not to disrupt the jacking operations or transit of the rig.

For the protection of a semi-submersible rig, anodes installed on the columns and hull or Pontoon would be flush mounted to minimize resistance during transit.

Internal areas of the spud can or mat are invariably fitted with sacrificial anodes. The type and quantity of anodes are designed to ensure every compartment and corners of the tank internals are receiving full protection until the end of the anode design life.

Submerged fixed structural steel in a marine environment is one of the most critical areas for cathodic protection. Steel piling of these structures is often coated to some 3 to 5 metres. Below low water and is left bare below the depth Designers of these structures rely predominantly on cathodic protection to protect submerged and buried steel surfaces. With sacrificial anode systems, a large number of anodes are distributed throughout the piles and because of the even distribution of anodes,the level of protection is usually very uniform.

Wharves or jetties steel piles

Deep-water has provided cathodic protection for every type of dock and jetty structure. Whether designing an anode system for a new construction project or retrofitting the anodes on an old harbor, our team understands that every asset is different, both structurally and in terms of its particular corrosive environment. To accommodate all of the variables involved with a marine cathodic protection system (water depth, tide, temperature, salinity, etc.) one must design with multiple solutions in mind. At Deep-water, our NACE - certified corrosion experts apply a suite of different proprietary products, each designed to suit a particular environment. All of Deep water’s system components are designed and manufactured in-house. By utilizing the full range of products and methods developed during our long history, our team can quickly and reliably address the various challenges involved in protecting these types of assets.

Ship hull

Corrosion is one of the greatest enemies of the ship and its machinery. It is also the toughest enemy to fight against, for the people working on the ship.

Iron is one substance which is used in abundance on the ship. From the main body of the ship to the smallest equipment used in operations, iron makes its presence felt in almost every type of equipment used onboard.

Iron is also the most corrosion-prone material when it comes in contact with air and water. A ship is continuously in contact with water and moisture-laden winds which makes it highly susceptible to corrosion. The outer body of the ship (mainly hull) is continuously in contact with water, making it extremely vulnerable to corrosion.

It is for this reason sacrificial anodes are used to protect the parent material and UCPI also supply and installation of SACP.

Oil platforms

The entire steel platform acts as a cathode, stopping the electrochemical process in corrosion from occurring and preserving the structure. Sacrificial anodes are another form of cathodic protection designed to shield structures from corrosion. UCPI provides both SACP & ICCP.

Stop Log gates

Cathodic protection (CP) is a technique used to control the corrosion of stop log gate surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode. The sacrificial metal then corrodes instead of the protected metal. An external DC electrical power source is also used to provide sufficient current to the structure. UCPI provides both SACP & ICCP.

Heat Exchanger

Heat exchangers are usually protected against corrosion by the impressed current cathodic protection. The solution of protection against corrosion of heat exchanger tubes by this invention is based upon the use of the mobile sacrificial anodes. And UCPI have got a project from Power Source Corporation Ltd, Philippines on Heat Exchanger, we did ICCP for them and we are completed this project successfully.

We are ready to help

Consult Our Experts

The Company based on a group of dynamic & highly experienced IIT Engineers in the field of CORROSION PREVENTION & CATHODIC PROTECTION to safeguard important infrastructures, installations & facilities from corrosion.

Need more information?

Please email us and our support staff will contact you back